- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

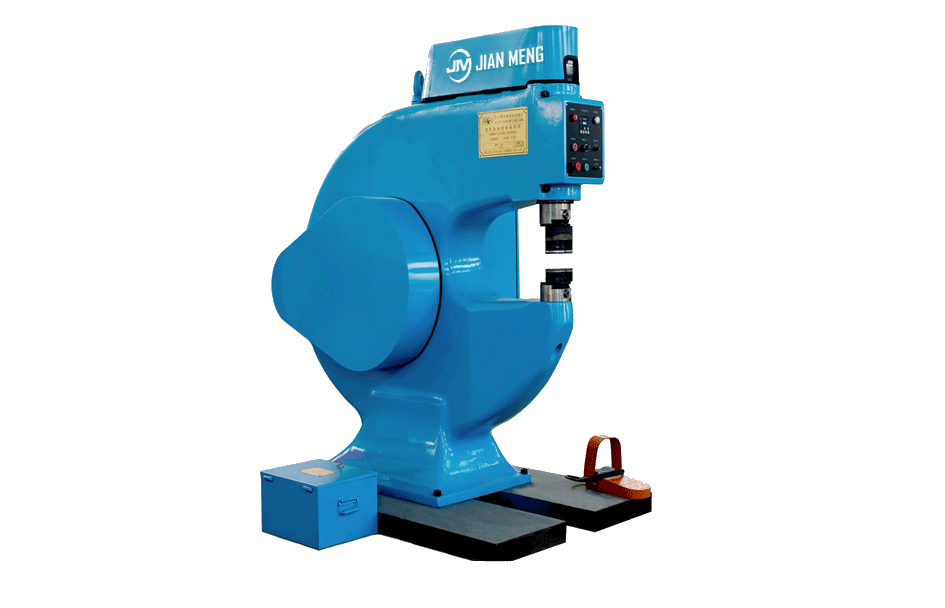

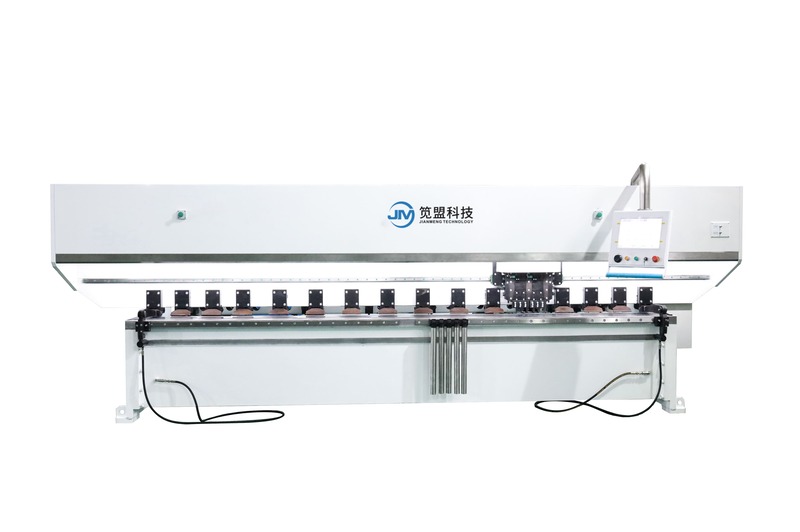

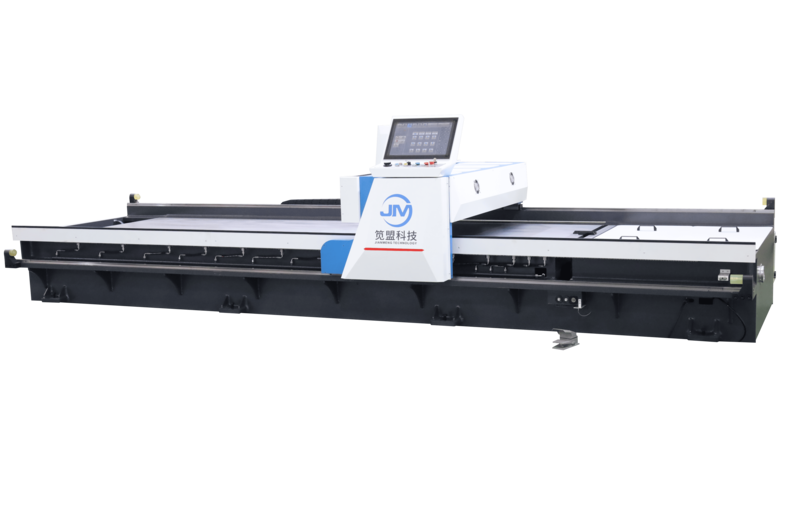

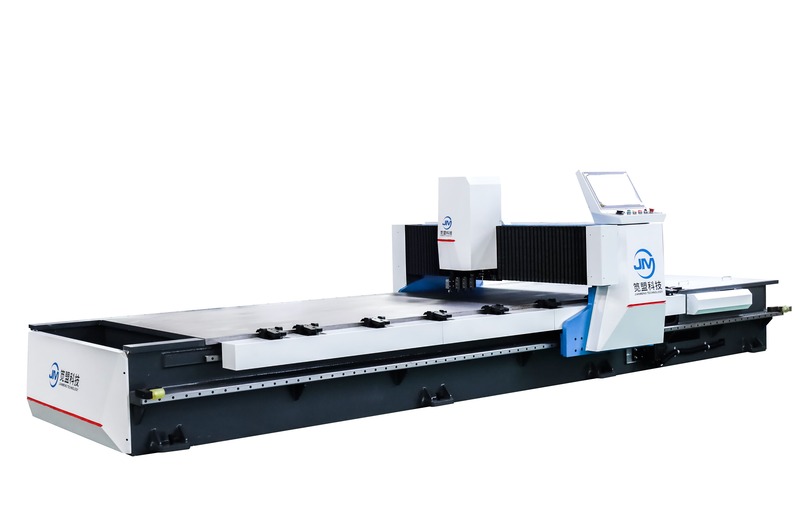

China Deburring & Chamfering Machine Manufacturers, Suppliers, Factory

This all-in-one solution is engineered for high-efficiency surface treatment of laser-cut and stamped metal parts. It integrates abrasive belt grinding, omnidirectional roller brush chamfering, and a magnetic adsorption conveyor to ensure consistent burr removal and a uniform brushed finish. With a gantry-milled welded steel frame and <0.02mm table flatness tolerance, the machine delivers long-term structural stability and precision.

Equipped with a Delta touchscreen and PLC module, it supports parameterized programming, real-time monitoring, and intelligent fault alerts. Featuring a wet dust collection system and patented technologies like belt deviation correction and automatic adsorption chamber cleaning, it is the ideal choice for manufacturers seeking to enhance surface quality and production efficiency.

- View as