- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

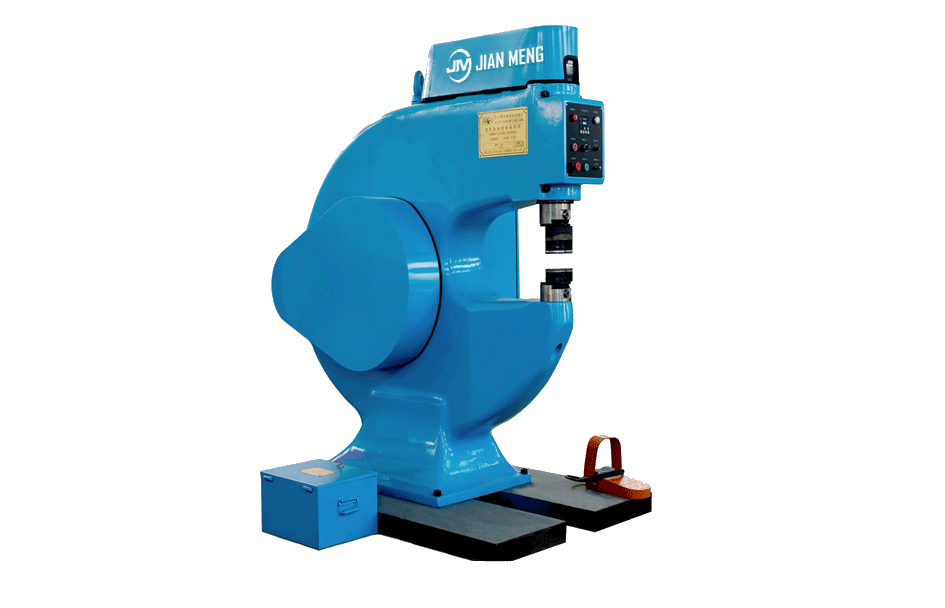

China Deburring Polishing & Brushing Machine Manufacturers, Suppliers, Factory

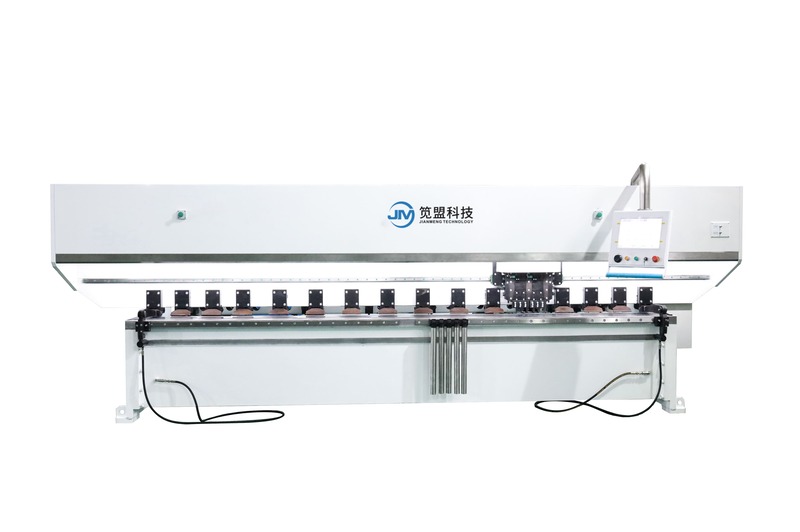

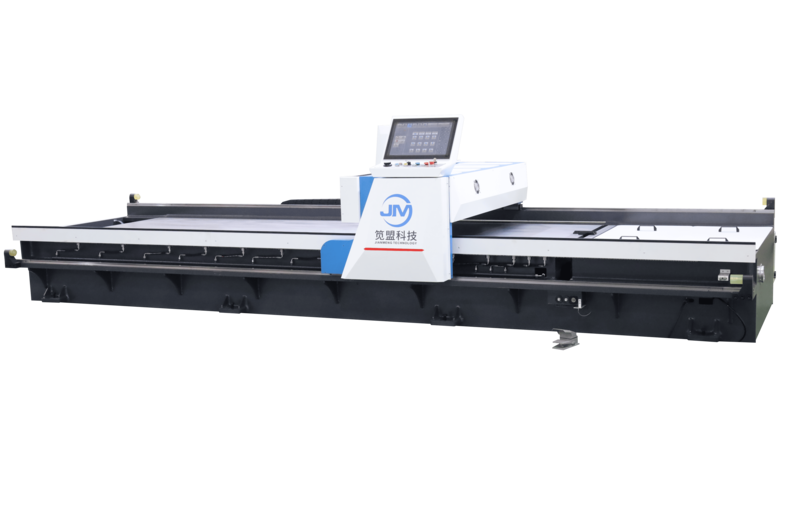

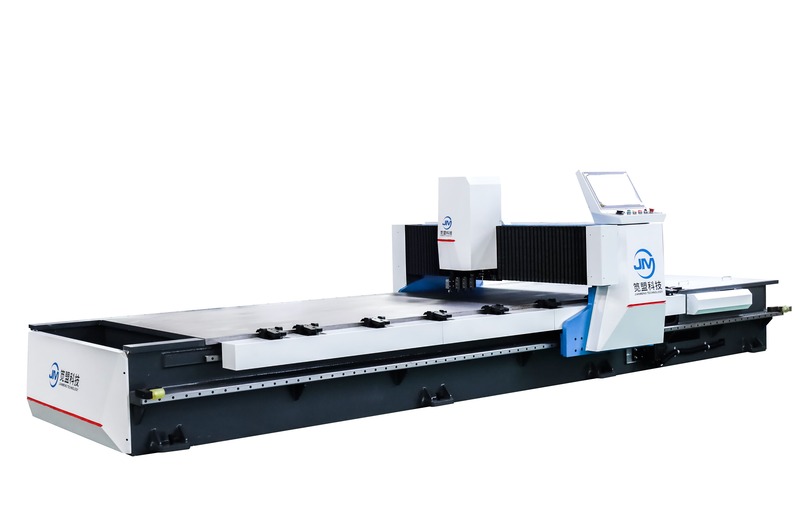

The Deburring, Polishing & Brushing Machine, developed by JIANMENG, is a high-performance metal surface treatment system that integrates deburring, chamfering, and abrasive brushing in one. Core functions include abrasive belt grinding, dual-axis roller brush chamfering, and a high-negative-pressure vacuum system, enabling efficient removal of burrs and slag while delivering a consistent brushed finish. A high-friction rubber conveyor and 15kW high-power vacuum fan ensure stable and reliable workpiece handling.

This machine further enhances operational efficiency and safety, supporting continuous 20-hour operation. It significantly improves surface treatment quality and production throughput, making it an ideal solution for post-processing stamped and laser-cut sheet metal parts, and perfectly suited for demanding metal fabrication environments.

- View as

CNC Deburring Polishing & Brushing Machine

JM is a leading manufacturer specializing in the production of advanced Deburring Polishing & Brushing Machines, designed to meet the highest standards of modern metal surface processing. This highly efficient and intelligent equipment seamlessly integrates deburring, polishing, oxide layer removal, chamfering, and metal surface brushing into a single process. The Deburring Polishing & Brushing Machine is widely applied in sheet metal fabrication, automotive parts manufacturing, precision instrument production, and other industries requiring superior surface quality. It effectively eliminates burrs, sharp edges, and surface irregularities from a wide range of metal materials such as stainless steel, carbon steel, aluminum, and copper, ensuring smooth and safe edges. Engineered for hi......

Read MoreSend Inquiry