- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

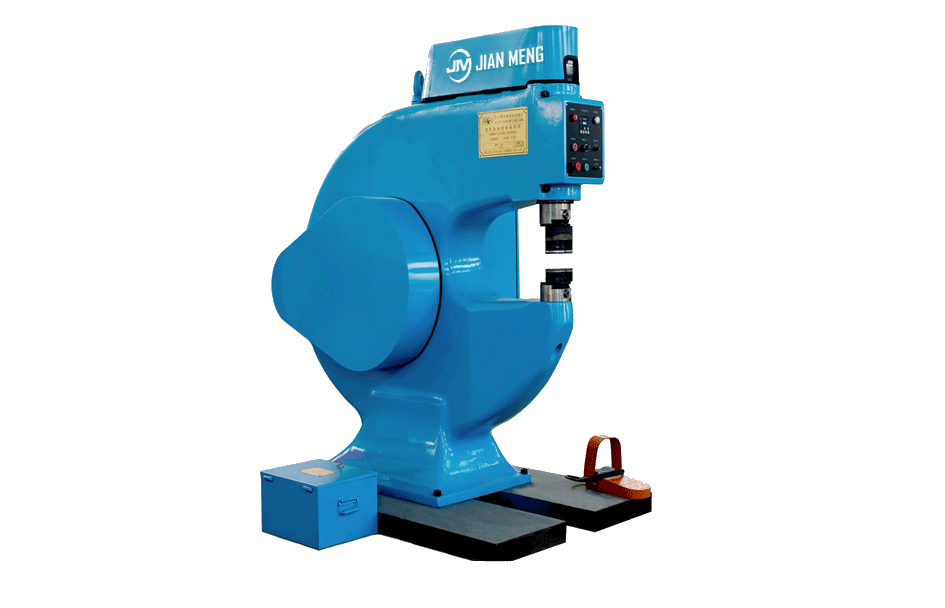

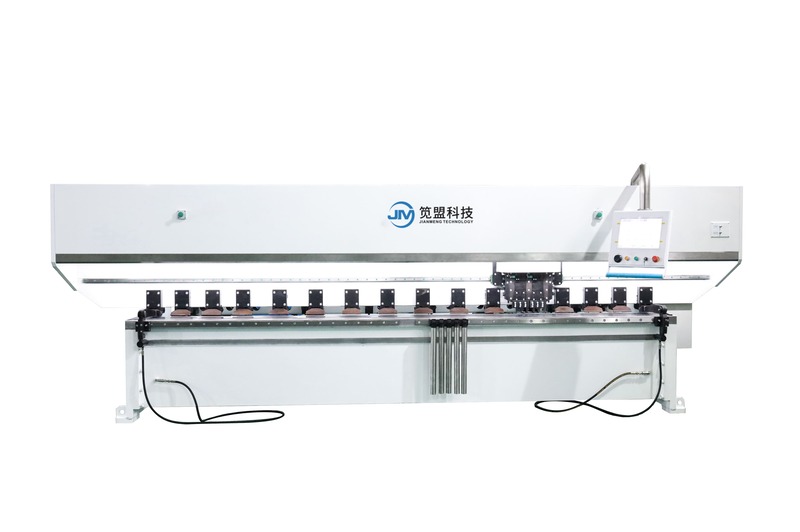

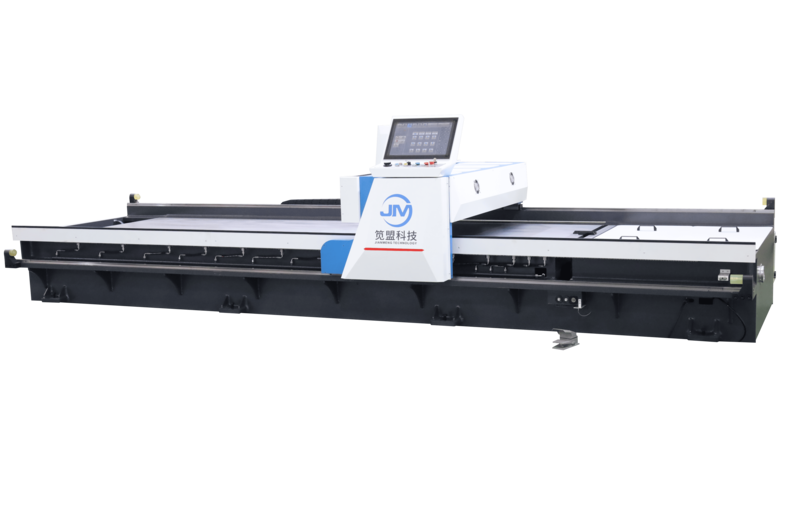

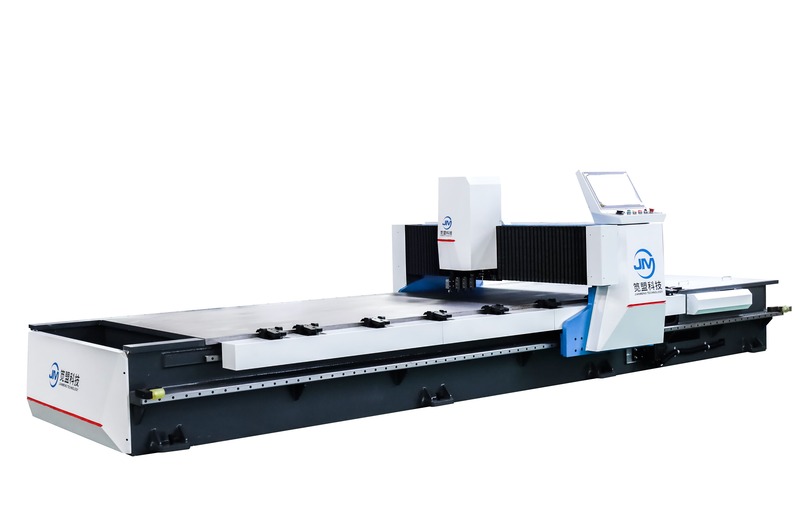

Hydraulic Press Brake

JM is a leading China Hydraulic Press Brake manufacturers. Jianmeng as the professional sheet metal equipment manufacturer in China has a standardized rack production workshop, with technological innovation as its core advantage. JIANMENG hydraulic press brake can support Max. 4+1 Axis and higher working speed, it is the best choice to meet demands in today's competitive markets.

Send Inquiry

The Hydraulic Press Brake manufactured by the Chinese manufacturer JM is the best choice for the startup company to save money or anyone who wants to use the machine in the easy way.

Machine model and number of control shafts

Number of control axes: 4+1

Reserved intelligent bending manipulator interface function

Main configuration of the machine

Special body of WE67K electrohydraulic machine, aging and normalizing treatment.

Rear stopper is equipped with high-performance servo motor and ball screw.

Standard Dutch DELEM-DA53T fully integrated CNC system.

1 set of standard upper and lower mould of the same tonnage (lower mould are designed according to bending products).

Main imported accessories of Hydraulic Press Brake

- CNC system: Netherlands DELEM

- Hydraulic system: Rexroth

- Grating ruler: GIVI

- High pressure oil pump: SUNNY

- Low-voltage apparatus: Schneider

- Oil pipe joint: DEGUO

- Seal: Parker

Main technical parameters of the machine:

| 1. | Nominal pressure | KN | 1300 | ||

| 2 | Bending Langth | mm | 3000 | ||

| 3 | Colum spacing | mm | 1300 | ||

| 4. | cylinder stroke | mm | 120 | ||

| 5. | Maximm opening heigh | mm | 370 | ||

| 6 | throat depth | mm | 25 | ||

| 7 | slide motion speed | carrying idler | m/ | 18 | |

| 8 | working | mm /s | 10 | ||

| 9 | retun trip | mm/s | 16 | ||

| 10 | Main motor power(national standard | KN | 5.5 | ||

| 11 | 8lide Yl,Y2accuracy | 8lider repeat acct ac! | mm | ≤±0.01 | |

| 12 | 8lide positioning accuracy | mm | ≤±0.02 | ||

Machine structure characteristics and standard configuration

The frame is welded in steel, eliminating internal stress by normalizing and high frequency vibration, guaranteeing the overall accuracy of the machine tool, having the best rigidity, excellent anti-twisting and anti-tilting ability. Thicker workbench plate and thicker slider make the machine very rigid. Therefore, when bending, the deformation of slider and workbench is very small and the workpiece has excellent linearity and angle uniformity.

Use large floor boring-milling machine and one-time machining method after integral welding to make precision machining to ensure machining accuracy.

Technical characteristics of equipment of Hydraulic Press Brake

The special hydraulic system (electro-hydraulic proportional servo synchronization control system) of Rexroth bending machine in Germany is adopted. The system is a position control system, closed loop type. It dynamically detects the synchronization error of the slide block through the grating ruler. The electro-hydraulic servo valve of the numerical control system corrects the synchronization error of the slide block, so that the slide block can always keep parallel with the workbench under the condition of complete partial load. The synchronous accuracy of sliding block is ≤±0.02mm.

The numerical control system controls the opening size of the proportional valve, and the proportional valve regulates the oil inlet of the left and right oil cylinders. The Y1 and Y2 axes -- the left and right sides of the slide block are respectively equipped with the GIVI high-precision linear grating scale (Y1-Y2) of the European ATEK company, which is used to measure the exact distance between the slide block and the workbench. The grating scale and the column are soft connected, and the column deformation will not affect the positioning. The position data is immediately fed back to the CNC system, which can calculate the output servo valve control signal (S1-S2). Thus, the positioning accuracy of slider is ≤±0.02mm.