- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

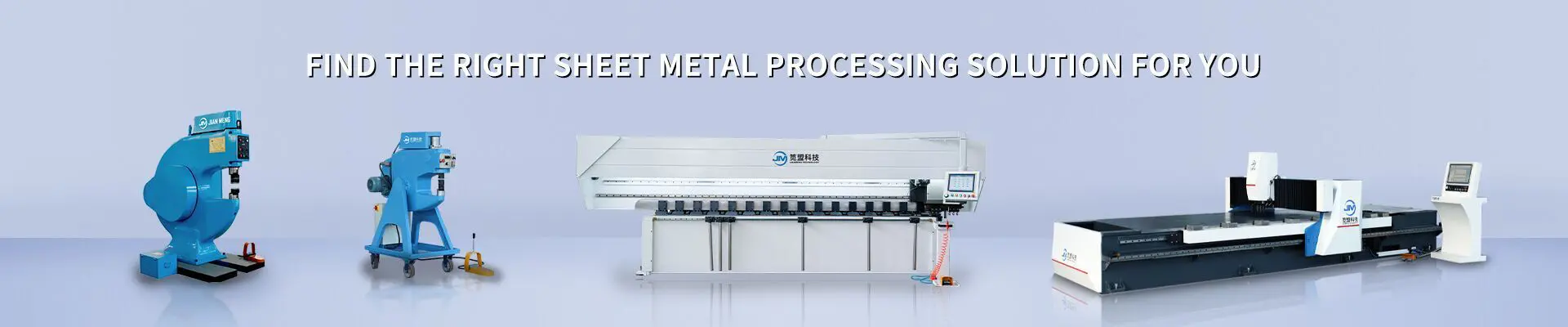

Maintenance of Horizontal Double Drive V Cutting Machine for Stainless Steel Plate

2024-05-10

Horizontal Double Drive V Cutting Machine for Stainless Steel Plate is a machine specially used for cutting stainless steel plates. It adopts a dual driving system, which can achieve higher cutting speed and faster processing efficiency. Compared with traditional cutting machines, the horizontal double drive V cutting machine for stainless steel plate has faster cutting speed, higher cutting accuracy, and better cutting quality.

Regularly clean the machine. The machine should be cleaned regularly to avoid dust, dirt, and other substances from adhering to the machine, which can affect its accuracy and service life.

Regularly check the machine's lubricating oil. Lubricating oil is essential for the machine's normal operation, and the oil should be checked regularly and lubricating oil should be added as needed to prevent the machine from overheating, wearing, and generating excessive noise due to friction.

Regularly check machine's the sensors and control systems to ensure their normal operation. If a fault is found, it must be repaired or replaced in a timely manner.

Regularly check the machine's cutting head to ensure its sharpness and straightness. Ensuring the quality and condition of the cutting head can effectively improve the machine's cutting accuracy and quality.

Regularly calibrate the Horizontal Double Drive V Cutting Machine for Stainless Steel Plate position accuracy. Inaccurate position accuracy can affect the machine's cutting accuracy and quality. Therefore, it is important to regularly calibrate the machine's position accuracy.