- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

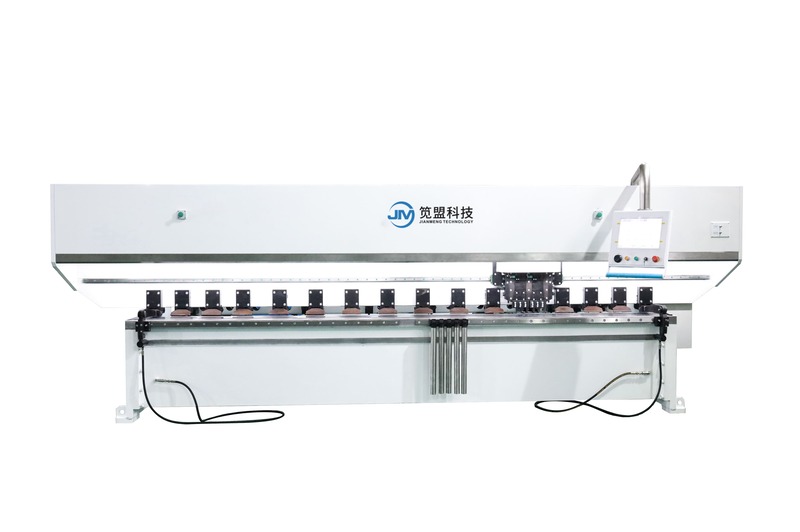

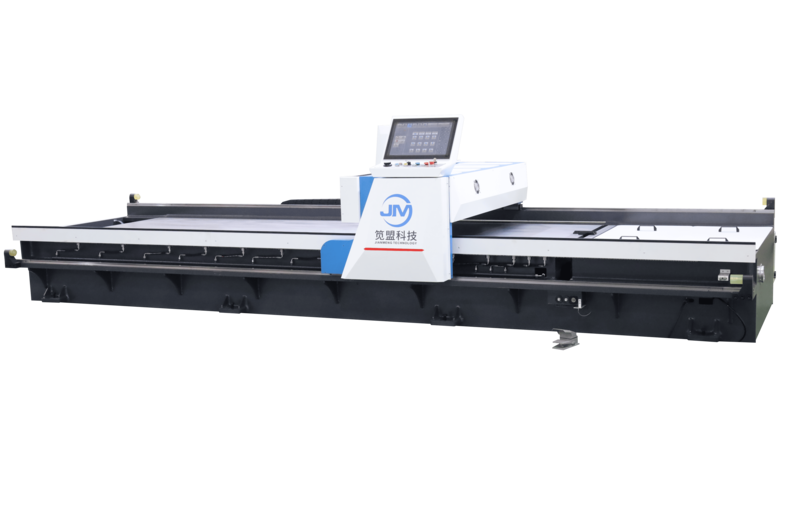

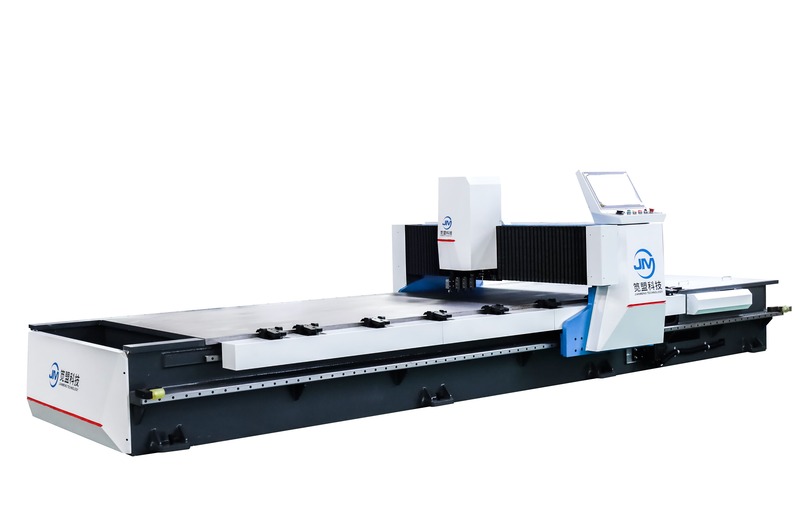

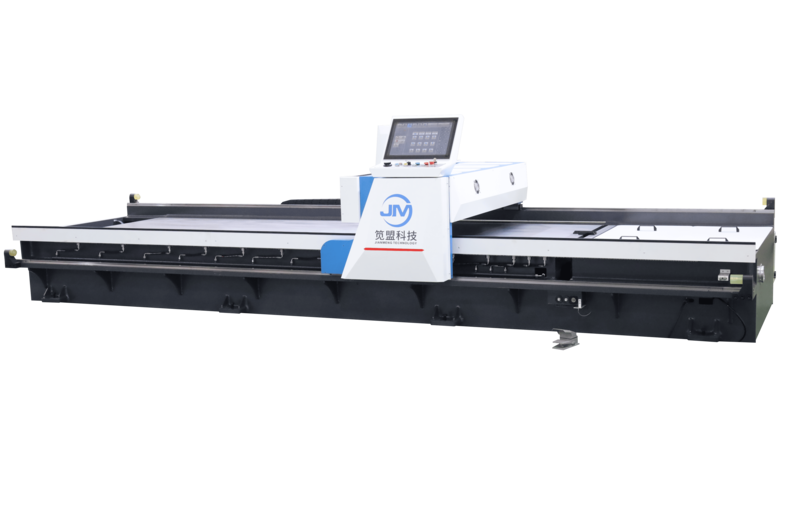

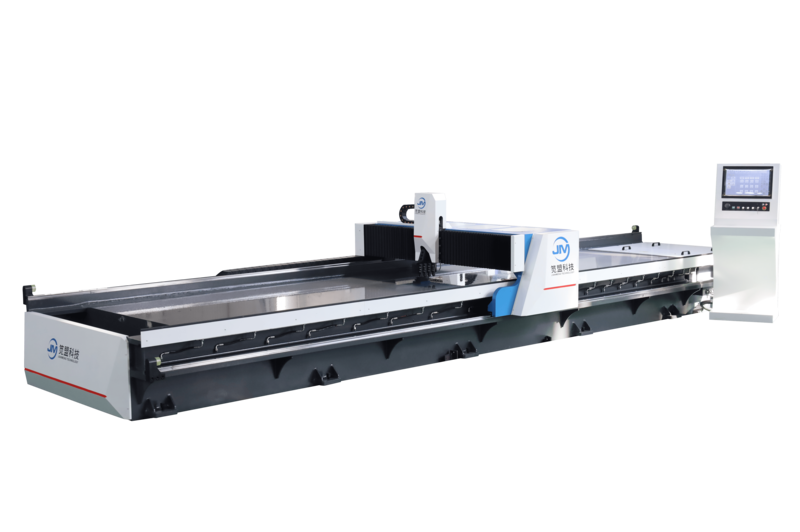

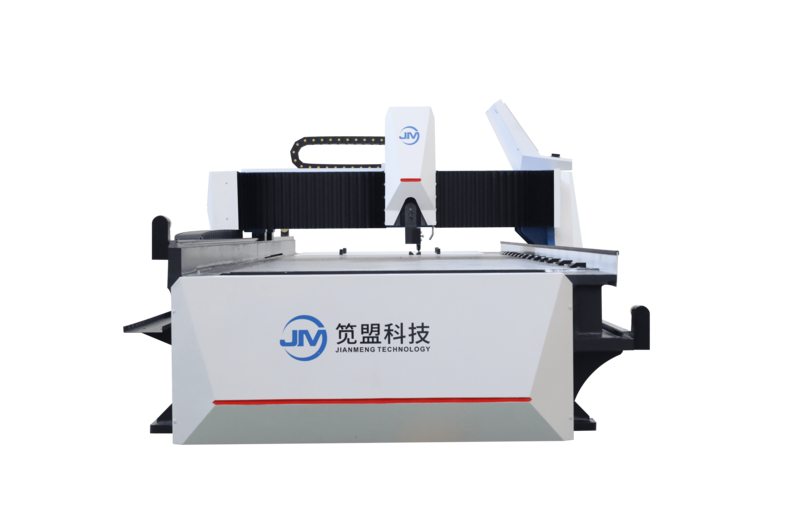

Sheet Metal V Grooving Machine

JM is a leading China Sheet Metal V Grooving Machine manufacturer. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry.JIANMENG provides various solutions, making metal fabrication easier!

Model:GSHM 1250×4000 GSHM 1500×4000 Customized

Send Inquiry

| Product name |

CNC Sheet Metal V Grooving Machine |

|

Brand |

JIANMENG |

|

Size |

1250×4000,1500×4000 or custom |

|

Maximum shaft speed parallel to X-axis |

130mm/min |

|

Working area |

1250×4000,1500×4000 or custom |

|

Certification |

CE,ISO9001 |

| Usages |

Architectural decoration, bathroom, kitchenware, door industry, elevator equipment, advertising signs, equipment casings, aluminum curtain walls,Automobile manufacturing, mechanical equipment, electrical equipment, precision parts, hardware products, aluminum copper products, etc |

• Low Bending Accuracy: Significant deviation in angle and size, affecting product quality.

• Die Interference for Complex Workpieces: Bending dies obstruct each other, preventing finished product completion.

• Complex Operation & High Personnel Requirements: Requires skilled operators with extensive experience.

• High Equipment Cost: Expensive, increasing production costs and investment risks.

• Poor Stability & Frequent Breakdowns: Regular malfunctions disrupt production and increase maintenance costs.

• Slow Processing Speed: Long processing time reduces overall production efficiency.

• Better Accuracy: Precise grooves improve bending precision.

• Reduced Interference: Eases complex workpiece bending and minimizes die issues.

• Simpler Operation: Standardized process lowers operator skill requirements.

• Lower Costs: In-house production reduces equipment costs.

• Higher Stability: Optimized design and quality parts reduce malfunctions.

• Faster Speed: Streamlines bending, boosting production efficiency.

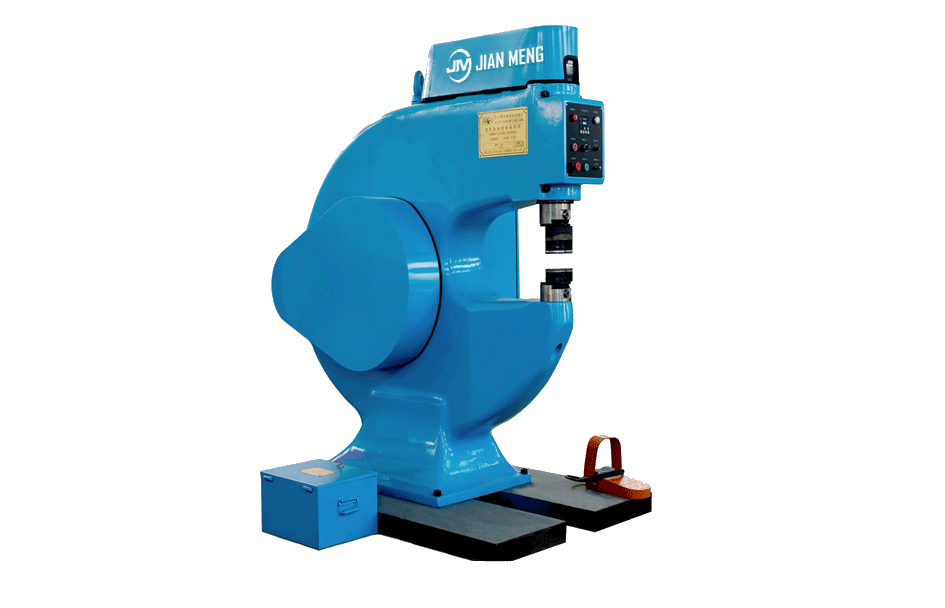

JIANMENG Intelligent has focused on CNC grooving machine for 15 years. It is the manufacturer with the largest variety of V CNC grooving machines in the country and is a comprehensive enterprise integrating the R&D, production, sales and after-sales service of CNC v cut machine.

JIANMENG Intelligent has a standardized rack production workshop. With technological innovation as its core advantage, it cooperates with multiple international accessory manufacturers for R&D. Currently, it has a number of intelligent CNC v grooving machine. It helps provide high-quality exclusive v groove machine solutions for multiple industries such as stainless steel processing, architectural decoration, bathroom, kitchenware, door industry, automotive manufacturing, hotel kitchen equipment, elevator equipment, advertising signage, anti-slip plates, display props, hardware products, etc.

JIANMENG Certifications

• CE Certification: Complies with EU health, safety, and environmental regulations.

• ISO Certification: Ensures consistent quality through international standards.

• Patent Certificate: Highlights the uniqueness and innovation of our technology.

Trusted by customers around the world

JIANMENG Philosophy

• Mutual Growth: We prioritize healthy, beneficial relationships with clients.

• Commitment: Focused on both business growth and personal development.

• Partnerships: Building shared success through collaboration.

• Vision: Cherishing relationships to create a brighter future together.

The commitment to high-quality core accessories

• Core Quality: High-quality v grooving machines rely on premium core accessories.

• Reliable Brands: We use trusted brands like Schneider, Siemens, Inovance, TBI, and Igus.

• Meticulous Manufacturing: Each machine is designed for durability, strength, and sustainability.

• Exceeding Expectations: Prioritizing quality ensures our machines surpass customer expectations in performance and efficiency.

Strict production processes and quality control

• Strict Protocols: We implement rigorous manufacturing processes to uphold high standards.

• Advanced Facilities: Equipped with cutting-edge technology and operated by skilled professionals.

• Attention to Detail: Ensures every grooving machine is consistent, reliable, and top-quality.

• Quality Control: Our comprehensive system gives customers confidence in the performance of JIANMENG v groove machines in any application.

Four simple steps to start and experience our rapid response service:

Step 1: Describe your needs

Fill out the contact form at the bottom of the page where you can find the phrase "Send Your Inquiry". Provide your email and detailed information about your needs, then click the "Send" button to complete the quote request process. Alternatively, you can click the "Chat with Supplier" button on the right side of the page to talk directly with a JIANMENG sales representative.

Step 2: Discuss your needs

Our sales team will contact you within 24 hours to discuss your specific needs and project requirements, providing tailor-made solutions to meet your exact specifications.

Step 3: Receive the quote and place the order

Receive a comprehensive quote within 48 hours, including product details, pricing, and delivery schedules. Confirm your order through our secure online platform, email, or phone.

Step 4: Fast production and delivery

Our advanced manufacturing process ensures fast production without compromising quality. We guarantee fast and reliable delivery and keep you informed every step of the way.

Q: What are your advantages?

A: Different from other factories. Our company has a professional QC (quality control) team. During the production process, they will be assigned to follow up on the order. Inspection reports will be sent to guests every week, with videos and pictures attached. In this case, guests can see the production of their orders in person. After the order is completed and packaged, we will provide customers with an order summary report. Our service provides customers with a good purchasing experience. All products exported by our company ensure the correct quality. If there are any quality problems when they reach the end user, we promise to claim compensation.

Q: How is your after-sales service?

A: Our company has a professional after-sales service team, ready to serve you at any time, we can provide multi-language video guidance tutorials, including installation and commissioning tutorials, equipment maintenance tutorials and sheet metal processing process tutorials, fast response and full technical support so that you have no worries.

Q: Can you send samples to my office for free?

A: We would like to provide you with samples for free, but I'm sorry that you have to pay for the shipping. After placing an order, we can send it to you.

Q: Do you have a factory?

A: Yes, we are one of the top three manufacturers of slotting machines in the world. We have a plant of 8,000 square meters and dozens of mechanical engineers. The factory supplies various types of slotting machines and ensures fast delivery.

Q: What is the difference between white steel knives and alloy knives? What products are they suitable for?

A: White steel knives can process all products, but stainless steel is easy to be blunt and burnt, so manual sharpening is required. It can adapt to all materials. Different models of alloy knives correspond to different materials, and they need to be selected and replaced with new ones when they are broken. Alloy knives are more efficient than white steel knives and have a longer single life, so alloy knives are more recommended.