- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

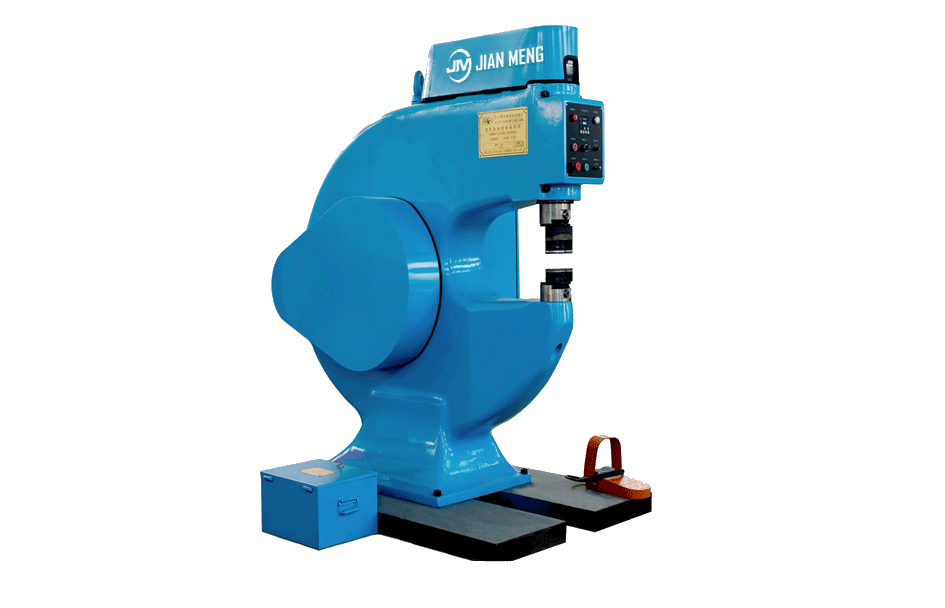

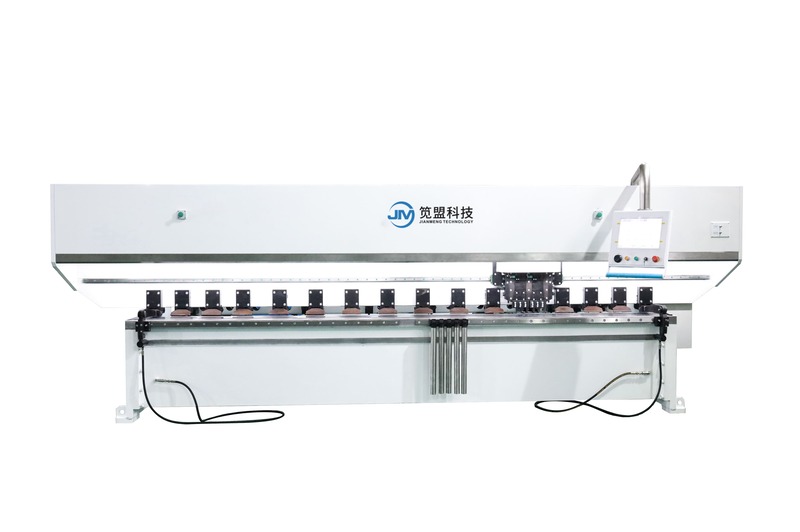

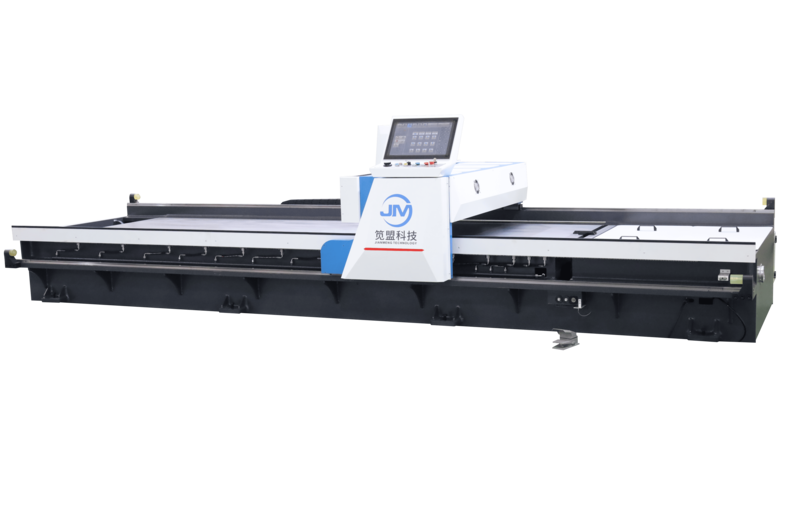

Horizontal CNC V Grooving Machine

High quality Horizontal CNC V Grooving Machine is offered by China manufacturer JM. Grooving machine is highly effective in precision work and corner bending to maintain edges. By using V grooving machine which is stable to bend metal sheets, they can be folded into tight, seamless workpieces.

Model:GSHM 1250×4000

Send Inquiry

Introduction

Horizontal CNC v grooving machine is used for processing metal sheets which is good for bending.CNC V cut machine ensures high accuracy and efficiency, allowing for complex designs and shapes.

Configuration

|

CNC system with large touch screen |

EASYCAT |

|

Hydraulic control system |

Japan Yuken |

|

Servo motor |

EASYCAT |

|

Planetary reducer |

Taiwan Lymin |

|

Cylinder sealing element |

Japan Valqua |

|

Proximity switch |

Japan Omron |

|

Single/double pole air switch |

France Schneider |

|

AC contactor |

France Schneider |

|

Micro/Thermal relay |

France Schneider |

|

Circuit breaker |

France Schneider |

|

Button |

France Schneider |

|

Bearing |

Japan SFK |

|

Alloy knife |

Korea Korloy |

|

Heavy linear guide rail |

Taiwan TBI |

|

Machine tool cable |

Germany Igus |

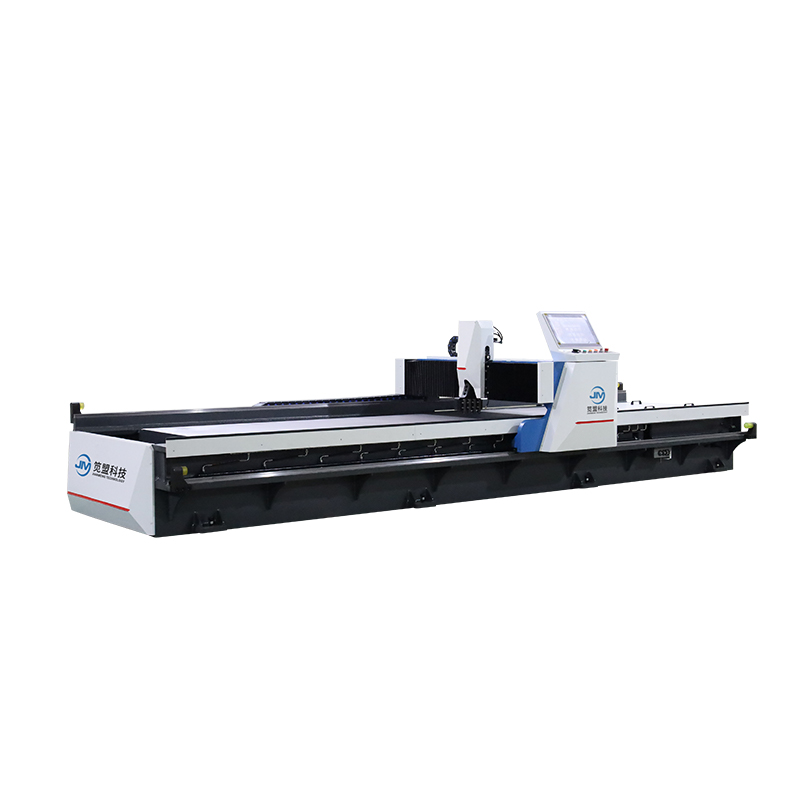

19 inch CNC touch display

-Drawing function

-Bending effect display

-Remote control function

-Four-axis control system, real-time monitoring of equipment status

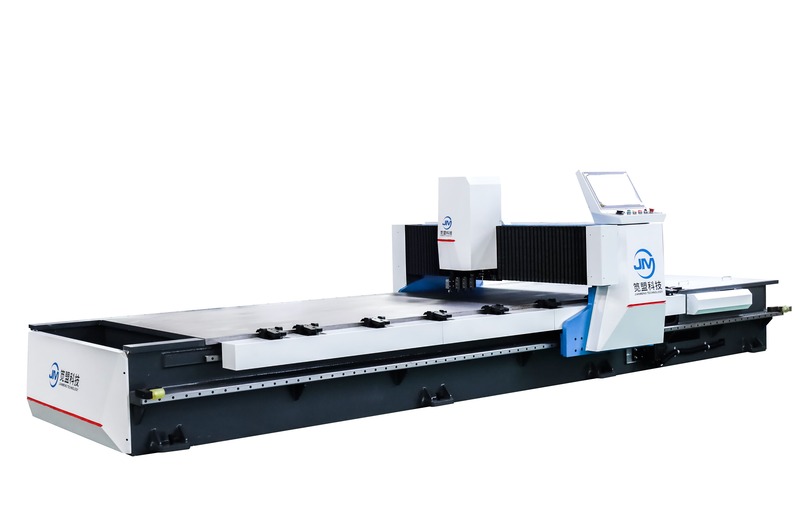

Gantry Frame

The v groover machine base and beam utilize a frame structure design, featuring a worktable made from 60mm low alloy high-strength structural steel, and the frame constructed with Q345B steel plate. This design ensures the machine tool's excellent overall rigidity, making it strong and durable.

-The tool holder of GSHM v grooving machine is equipped with four alloy cutters to process the V-shape groove, so the cutting amount is evenly distributed to reduce the deformation of the machined parts

-The universal tool clamping mounting surface can meet the clamping requirements of various tools

-The white steel tool and alloy tool are interchangeable

Parameter

|

Machinable range |

|

|

Maximum width of machinable sheet |

1250 mm |

|

Maximum length of machinable sheet |

4000 mm |

|

Maximum thickness of machinable sheet (stainless steel) |

5.0 mm |

|

Minimum thickness of machinable sheet |

0.4 mm |

|

Minimum distance from V-shaped groove to edge |

8.0 mm |

|

Planeness |

|

|

Table flatness |

±0.03mm |

|

Maximum shaft speed |

|

|

Maximum shaft speed parallel to X-axis |

120 m/min |

|

Maximum shaft speed parallel to Y1-axis |

60 m/min |

| Maximum shaft speed parallel to Y2-axis6 |

60 m/min |

|

Maximum shaft speed parallel to Z-axis |

10 m/min |

|

Positioning accuracy |

|

|

Axis positioning accuracy (X, Y1, Y2, Z) |

0.015mm |

|

Resolving power |

|

|

Axis resolution (X, Y1, Y2, Z) |

0.001mm |

|

Servo motor power |

|

|

X-axis servo motor power |

5.5 KW |

|

Y1-axis servo motor power |

1.0 KW |

|

Y2-axis servo motor power |

1.0 KW |

|

Z-axis servo motor power |

1.0 KW |

Our Case

Our friends in Thailand are very satisfied with our CNC V Cut Machine.They have been using them for many years without any problems and will continue to cooperate with us in the future.

Application

Our CNC grooving machine is widely used in various metal processing industries such as architectural decoration, sanitary ware, kitchenware, door manufacturing, elevator equipment, advertising signage, equipment enclosures, and aluminum curtain walls. Many customers also use this v grooving machine in the automotive manufacturing, machinery, electrical equipment, precision parts, hardware products, and aluminum and copper products industries.