- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

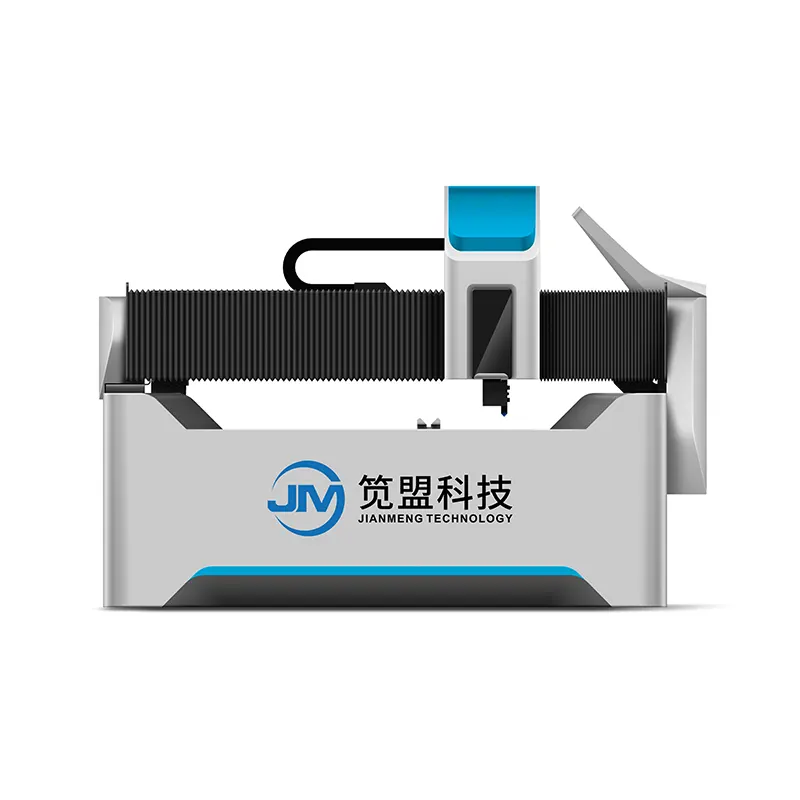

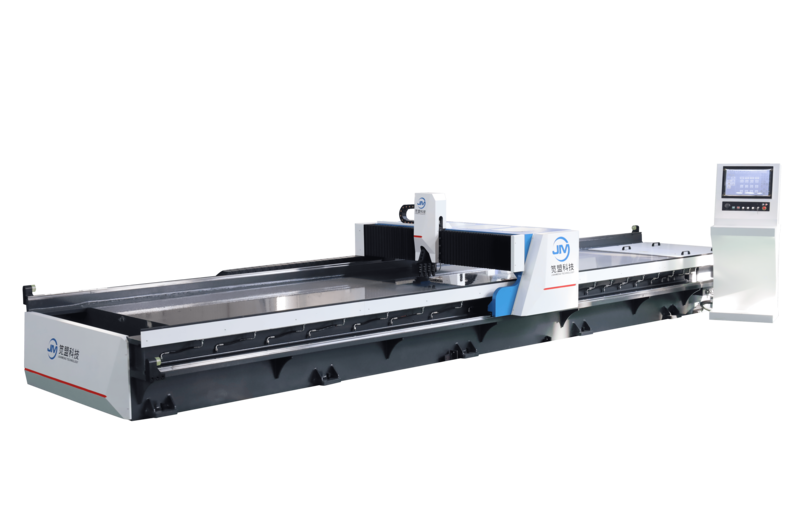

China CNC V Grooving Machine Manufacturers, Suppliers, Factory

We insist on offering high-quality output with superior small business concept, honest profits along with the best and fast service. it will bring you not only the top quality product and huge profit, but one of the most significant will be to occupy the endless market for CNC V Grooving Machine,Horizontal CNC V Groove Machine,Vertical CNC Grooving Machine,V Grooving,V Cutting Machine, We often hold the philosophy of win-win, and establish long-term cooperation connection with consumers from around the planet.We think that our expansion base on customer's achievement, credit rating is our daily life.

CNC V Grooving Machine, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

Hot Products

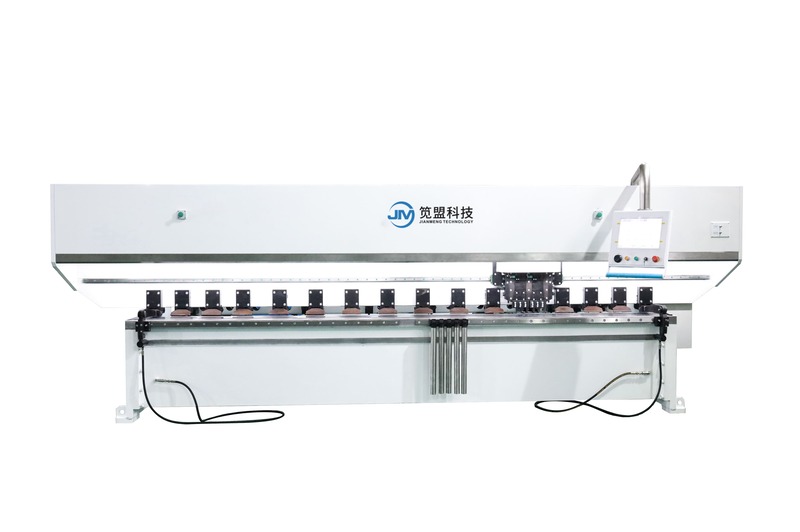

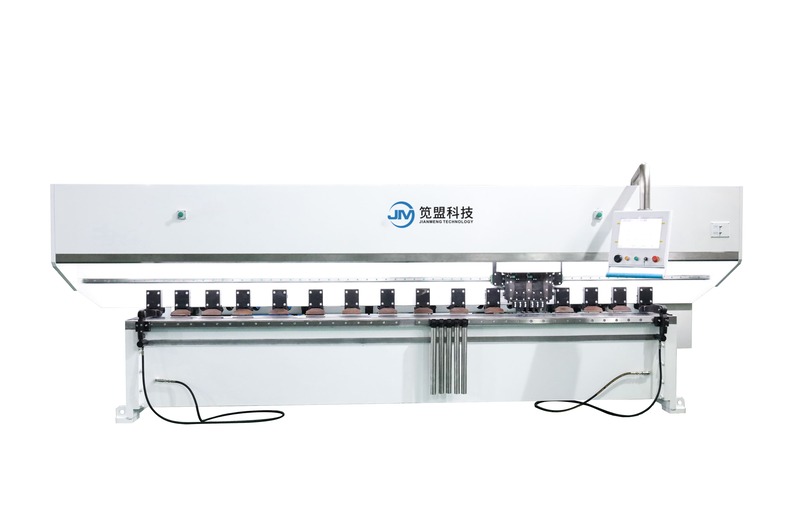

Vertical V Grooving Machine with Two Head

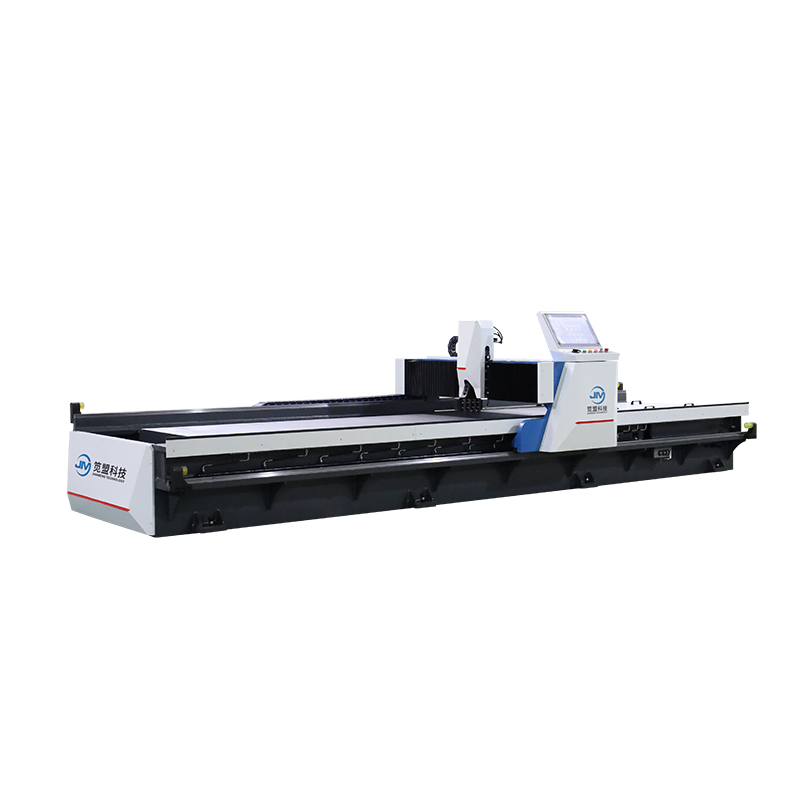

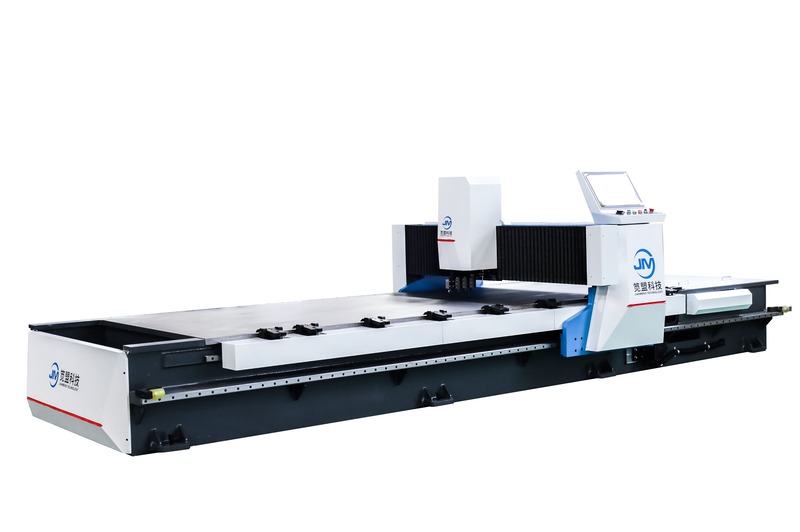

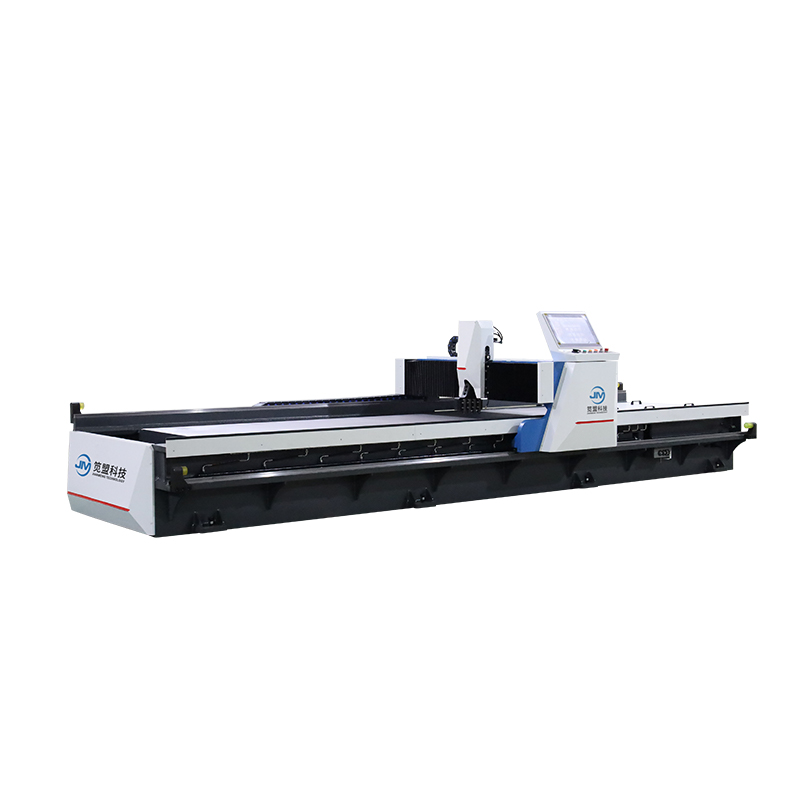

High quality Vertical V Grooving Machine with Two Head is offered by China manufacturer JM. Grooving machine is highly effective in precision work and corner bending to maintain edges. By using V grooving machine which is stable to bend metal sheets, they can be folded into tight, seamless workpieces.Horizontal Double Drive V Slotting Machine

As the professional V grooving machine manufacturer in China, JM produces the cost-effective horizontal double drive V slotting machine for processing metal plates, this machine is easy to master and operate.V-Shaped Grooving Machine

The horizontal high speed v-shaped grooving machine is a professional V grooving equipment produced by JM, a manufacturer in China with the most types of V grooving machines. The horizontal high speed v-shaped grooving machines have high economic benefits and cost-effectiveness at medium to low utilization rates.Sheet Metal CNC V Grooving Machine

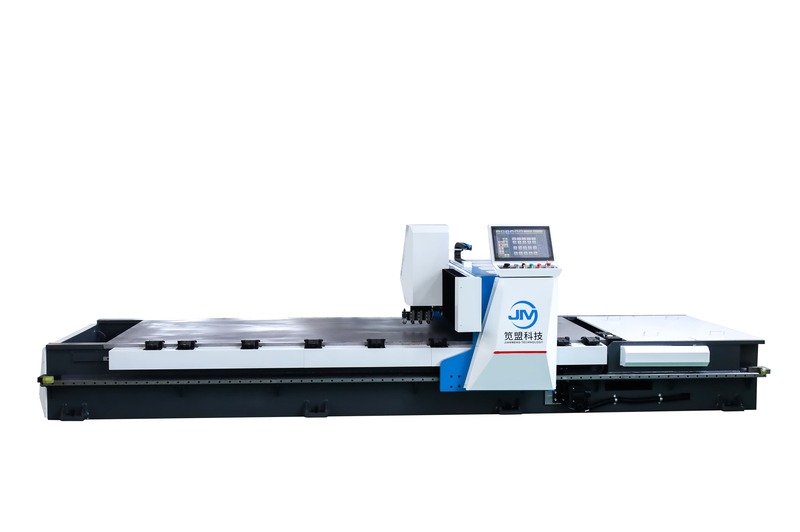

High quality Sheet Metal CNC V Grooving Machine is offered by China manufacturer JM. A metal sheet v grooving machine can create V-shaped grooves in stainless steel sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal plates. This allows the bent workpieces to have a very small edge radius, meeting the high precision and aesthetic demands of the high-end sheet metal decoration industry.JIANMENG provides various solutions, making metal fabrication easier!CNC Guillotine Shearing Machine

JM CNC Guillotine Shearing Machine is a commonly used shearing device in metal processing, primarily designed for cutting metal sheets of various thicknesses. It operates by applying a vertical downward motion of the upper blade against the lower blade, generating a shearing force to achieve precise cutting. It is mainly used for high-precision shearing of metal materials such as steel plates, stainless steel, and aluminum sheets. The shearing machine is widely applied in industries such as machinery manufacturing, automotive production, and electrical equipment manufacturing. The shearing method of the JM Guillotine Shearing Machine is similar to a "gate" moving up and down. Using hydraulic or mechanical transmission, the upper blade holder moves linearly downward along a fixed track (usually vertical or at an inclined angle) to shear metal sheets. With high shearing precision, it is especially suitable for cutting thick plates. JM shearing machine is designed for sheet metal processing, providing high-precision cutting solutions suitable for various metal sheets.CNC Vertical Back And Forth Grooving Machine

The V grooving machine manufacturer JM in China offers the leading CNC Vertical Back And Forth Grooving Machine. The CNC vertical back and forth V grooving machines completely solves the problem of deformation of working table, ensures the flatness of working table(+0.3mm),and solves the problem of depth accuracy affecting the quality of slotting.