- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

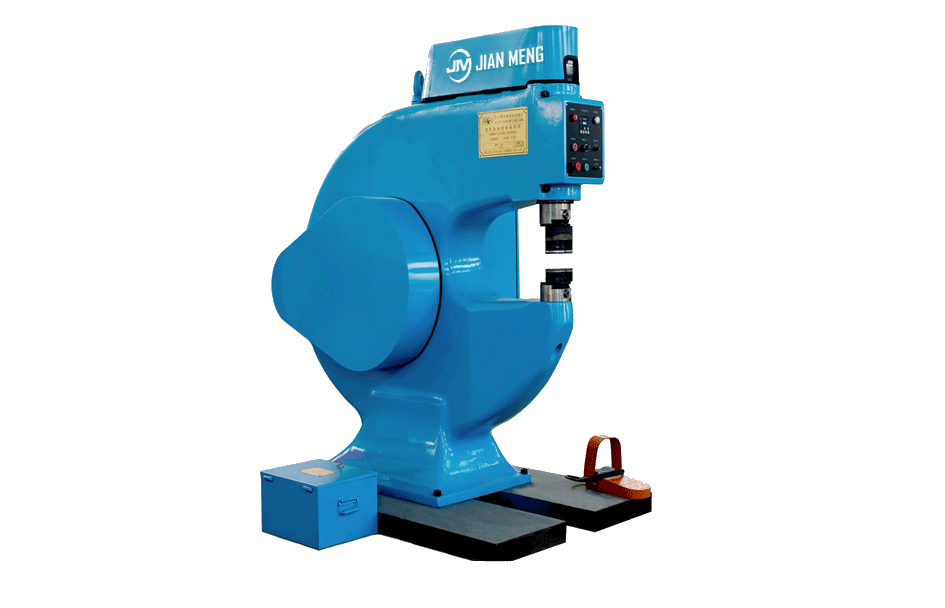

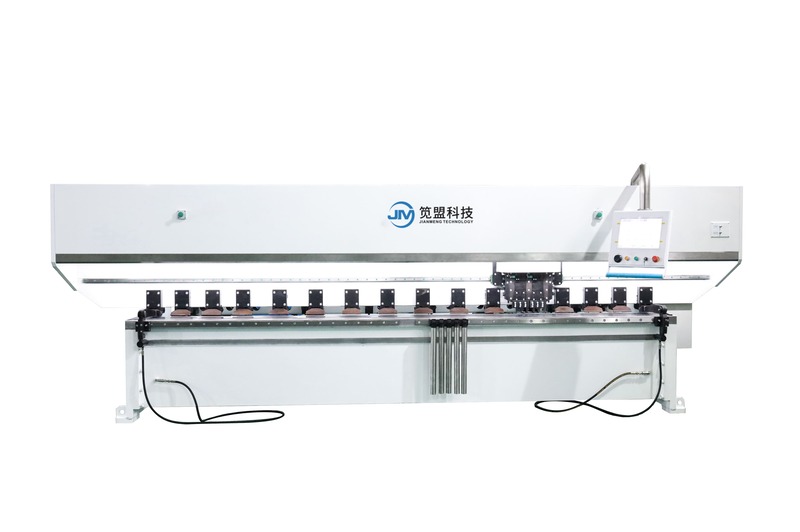

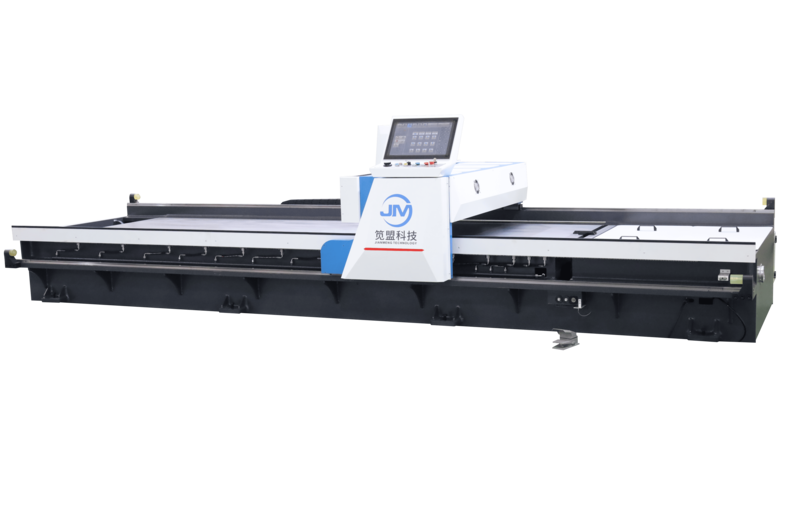

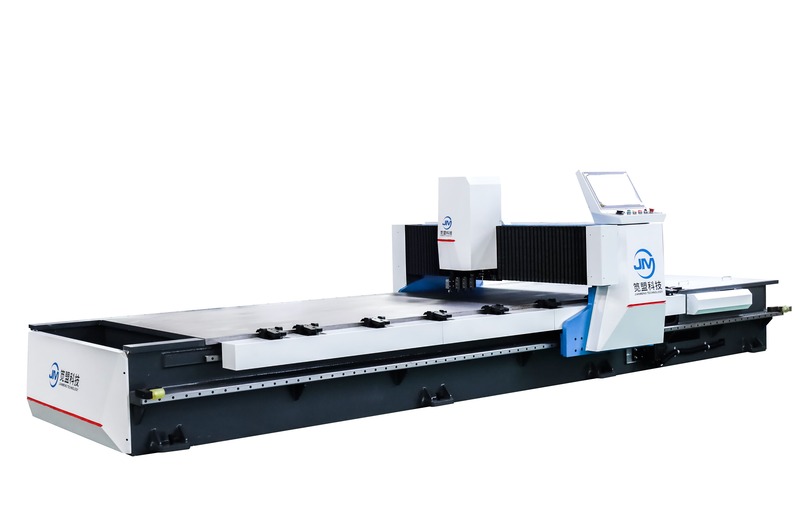

Vertical Back And Forth Grooving Machine

JM is a leading vertical back and forth grooving machine manufacturer in China. The vertical back and forth V grooving machines are updated products of traditional V grooving machine, which can be used for back and forth grooving, so as to improve the efficiency.

Send Inquiry

The Chinese manufacturer JM produces vertical back and forth grooving machines with high stability, strong rigidity and also convenient in usage.

Product Features:

1. Vertical back and forth grooving machine is used for back and forth grooving, to improve the efficiency.

2. Double tool for Vertical back and forth grooving machine carries back and forth working makes full use of the return time and power.

3. The worktable of vertical back and forth grooving machine have integrated operating platform, high frequency surface quenching, high hardness, there is no trace left when processing mirror plates.

Technical data of vertical back and forth grooving machine

| Processability | Processing Length | 2500mm | 3200 mm | 4000 mm | 6000mm |

| Processing Width | 1250/1500mm | 1250/1500mm | 1250/1500mm | 1250/150mm | |

| Processing Thickness | 0.4-5.0mm | 0.4-5.0mm | 0.4-50mm | 0.4-50mm | |

| Minimum edge distance | 8mm | 8mm | 8mm | 8mm | |

| Processing speed | Gantry(X-axis) | 0-120 m/min | 0-120m/min | 0-120 m/min | 0-120m/min |

| Tool holder(YI-axis)movement | 0-60 m/min | 0-60 m/min | 0-60 m/min | 0-60 m/min | |

| Movable clamping (Y2 axis) | 0-60 m/min | 0-60 m/min | 0-60 m/min | 0-60 m/min | |

| Tool holder (Z-axis)up and down | 0-10 m/min | 0-10 m/min | 0-10 m/min | 0-10m/min | |

| Processing accuracy | Repeated positioning ermror of positioning axis | 0.015mm | 0.015mm | 0.015mm | 0.015mm |

| Minimum resolution of positioning axis | 0.001mm | 0.001mm | 0.001mm | 0001mm | |

| Table | Table flatness | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03 mm |

|

Externa

|

Length | 4400mm | 5100 mm | 5900 mm | 7900mm |

| Processing Width | 2000/2250mm | 2000/2250mm | 2000/2250mm | 2000/2250mm | |

| Height | 1550mm | 1550 mm | 1550 mm | 1550mm |

Components of vertical back and forth grooving machine

- CNC system with large touch screen: Taiwan Superior

- Hydraulic control system: Janpan Yuken

- Servo motor: Taiwan Superior

- Planetary reducer: Taiwan Liming

- Cylinder seal element: Japan Valqua

- Proximity switch: Japan Omron

- Single/double air switch : France Schneider

- AC Contactor: France Schneider

- Button: France Schneider

- Thermal relay: France Schneider

- Circuit breaker: France Schneider

- Micro relay: France Schneider

- Alloy knife: Korea Korloy

- Heavy linear guide rail: Taiwan TBI

- Machine tool cable: Germany Igus

Applications Industry:

- Elevator equipment

- Door industry

- Architectural decoration

- Stainless steel processing

- Bathroom

- Advertising signage

- Kitchenware

- Hardware products

- Display props

FAQ

Q: How many days you need to install the vertical back and forth grooving machine?

A: Our vertical back and forth grooving machine is delivered to customer as a whole. It will take 3 hours for the installation and commissioning,then the machine can be used normally.

Q: Can you send your staff to install the vertical back and forth grooving machine for us?

A: Yes. We can arrange our engineers to offer on-site service, if you need it.

Q: Can you can design the machine according to our size?

A: Yes. We can design the vertical back and forth grooving machine according to your requirements.