- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

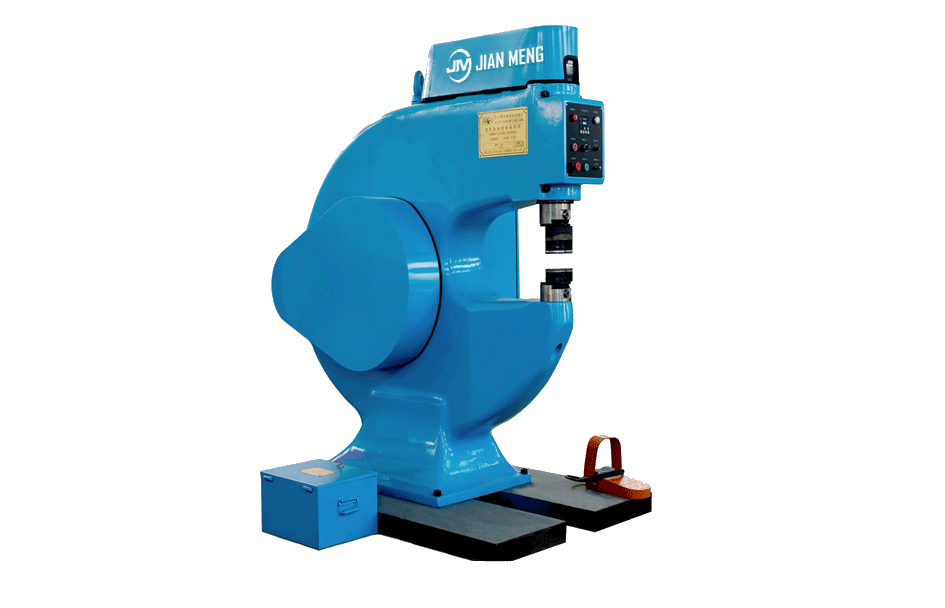

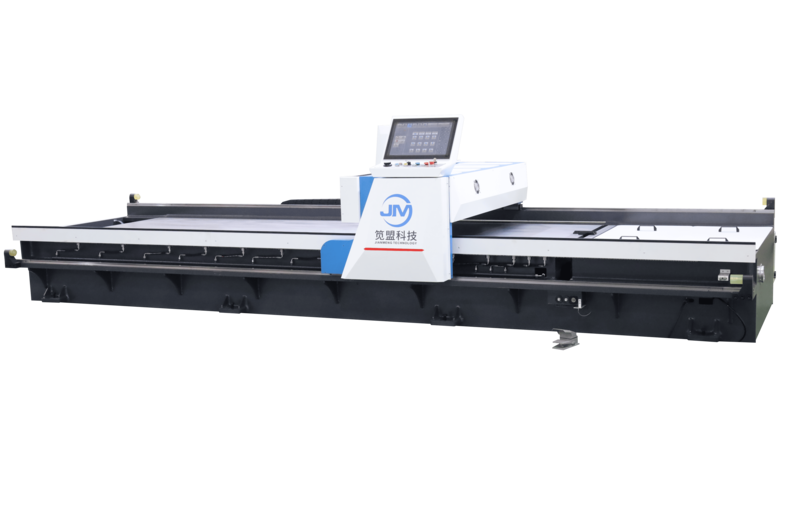

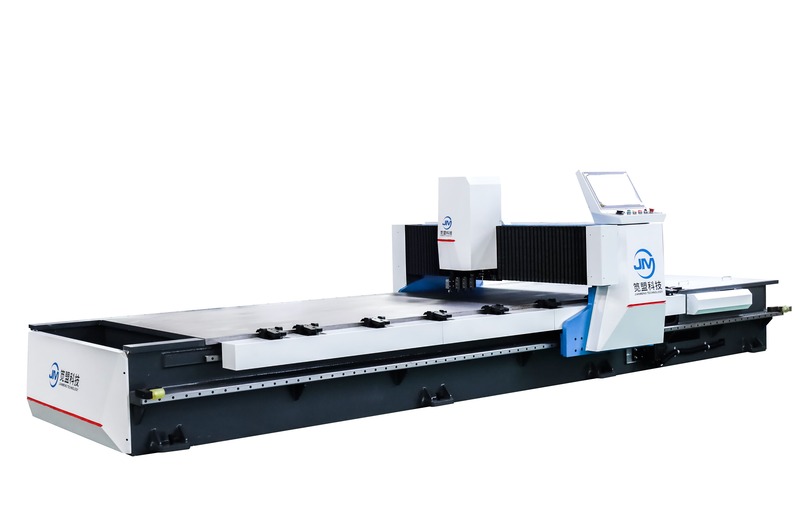

Vertical Back And Forth V Groove Cutting Machine

JM is the leading China V grooving machine manufacturer and supplier of vertical back and forth V groove cutting machine with affordable price. The vertical back and forth V groove cutting machine is the key equipment when process V-shaped grooves on mirror plates.

Send Inquiry

JM is a leading China Vertical Back And Forth V Groove Cutting Machine manufacturers. The vertical back and forth V groove cutting machines from Chinese manufacturer are strictly followed the machine tool process, and electric furnace tempering shall be adopted to eliminate welding stress and reduce equipment deformation.

Product Features:

1. The worktable of vertical back and forth V groove cutting machine have integrated operating platform, high frequency surface quenching, high hardness, there is no trace left when processing mirror plates.

2. Vertical back and forth V groove cutting machine is used for back and forth grooving, to improve the efficiency.

3. Double tool for Vertical back and forth V groove cutting machine carries back and forth working makes full use of the return time and power.

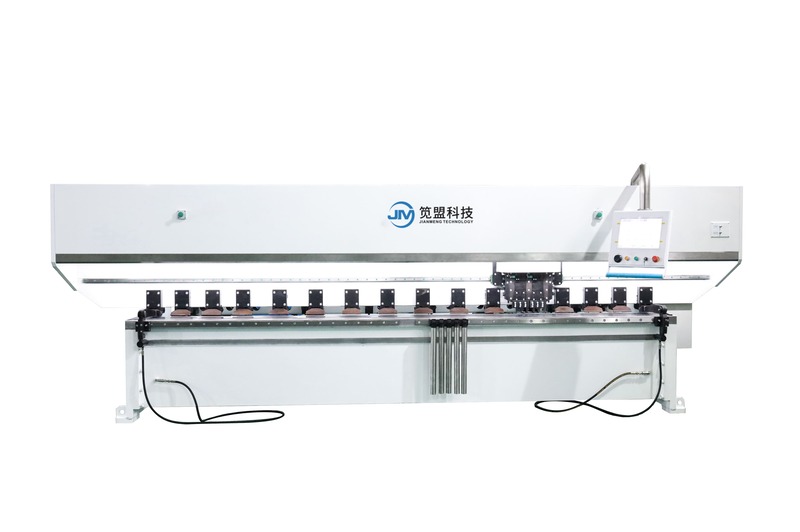

Technical data of vertical back and forth V groove cutting machine

| Processability | Processing Length | 2500mm | 3200 mm | 4000 mm | 6000mm |

| Processing Width | 1250/1500mm | 1250/1500mm | 1250/1500mm | 1250/150mm | |

| Processing Thickness | 0.4-5.0mm | 0.4-5.0mm | 0.4-50mm | 0.4-50mm | |

| Minimum edge distance | 8mm | 8mm | 8mm | 8mm | |

| Processing speed | Gantry(X-axis) | 0-120 m/min | 0-120m/min | 0-120 m/min | 0-120m/min |

| Tool holder(YI-axis)movement | 0-60 m/min | 0-60 m/min | 0-60 m/min | 0-60 m/min | |

| Movable clamping (Y2 axis) | 0-60 m/min | 0-60 m/min | 0-60 m/min | 0-60 m/min | |

| Tool holder (Z-axis)up and down | 0-10 m/min | 0-10 m/min | 0-10 m/min | 0-10m/min | |

| Processing accuracy | Repeated positioning ermror of positioning axis | 0.015mm | 0.015mm | 0.015mm | 0.015mm |

| Minimum resolution of positioning axis | 0.001mm | 0.001mm | 0.001mm | 0001mm | |

| Table | Table flatness | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03 mm |

|

Externa

|

Length | 4400mm | 5100 mm | 5900 mm | 7900mm |

| Processing Width | 2000/2250mm | 2000/2250mm | 2000/2250mm | 2000/2250mm | |

| Height | 1550mm | 1550 mm | 1550 mm | 1550mm |

Components of vertical back and forth V groove cutting machine

- CNC system with large touch screen: Taiwan Superior

- Hydraulic control system: Janpan Yuken

- Thermal relay: France Schneider

- Servo motor: Taiwan Superior

- Planetary reducer: Taiwan Liming

- Cylinder seal element: Japan Valqua

- Proximity switch: Japan Omron

- AC Contactor: France Schneider

- Button: France Schneider

- Circuit breaker: France Schneider

- Micro relay: France Schneider

- Alloy knife: Korea Korloy

- Single/double air switch : France Schneider

- Heavy linear guide rail: Taiwan TBI

- Machine tool cable: Germany Igus

Applications Industry:

Many industries need our vertical back and forth V groove cutting machine when they process mirror plate:

- Elevator equipment

- Door industry

- Architectural decoration

- Stainless steel processing

FAQ

Q: What is your MOQ?

A: 1set

Q: Can you can design the machine according to our size?

A: Yes. We can design the vertical back and forth grooving machine according to your requirements.

Q: Can you send your staff to install the vertical back and forth grooving machine for us?

A: Yes. We can arrange our engineers to offer on-site service, if you need it.