China V Groove Machine for Metal Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our improvement strategy for V Groove Machine for Metal,V Cut Machine,V Grooving Machine,Grooving Machine,V Grooving Machine for Sheet Metal, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

V Groove Machine for Metal, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we've got a pleasant and long terms business together!!!

Hot Products

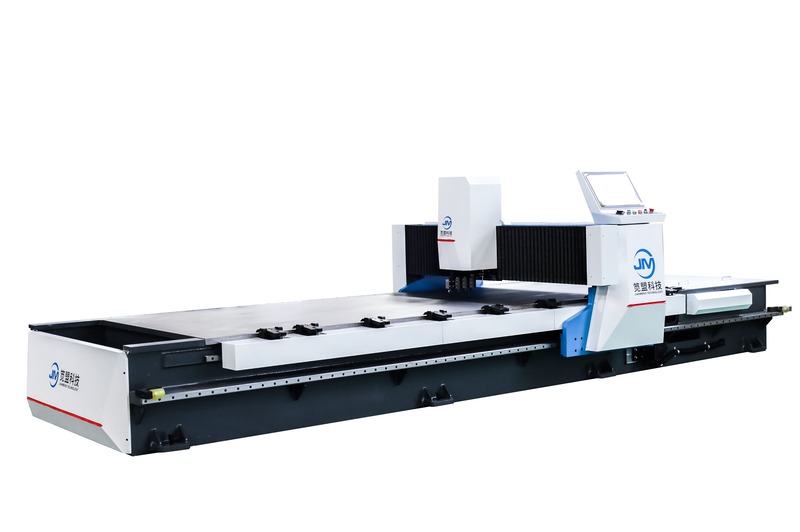

CNC Horizontal High Speed V Groove Cutting Machine

The CNC Horizontal High Speed V Groove Cutting Machine is a professional V cutting equipment from JM, the Chinese manufacturer with the most types of V grooving machines. At medium to low utilization rates, the CNC horizontal high speed V groove cutting machines have high cost-effectiveness and economic benefits .CNC Horizontal High Speed V Grooving Machine For Stainless Steel Plates

The CNC Horizontal High Speed V Grooving Machine For Stainless Steel Plates from Chinese manufacturer JM is not only to process stainless steel plate, but also can be used for cooper plates, aluminium plates, galvanized plates and son on.CNC Horizontal Double Drive V Groove Cutting Machine

The Chinese V grooving machine manufacturer JM has been focus on CNC Horizontal Double Drive V Groove Cutting Machine for many years. Its CNC horizontal double drive V groove cutting machine is effective and competitive in market.The CNC horizontal double drive V groove machine from Chinese manufacturer Jianmeng is equipped with intelligent system, easy to master and operate.Vertical High Speedv-Shaped Grooving Machine

The manufacturer JM in China has been focusing on Vertical High Speedv-Shaped Grooving Machine production over 10 years. The vertical high speed V grooving machine from Jianmeng has advantages in processing mirror plates.The Chinese V grooving machine manufacturer Jianmeng produces the best vertical high speed V-shaped grooving machine. The whole machine adopts frame structure and high strength bolt connection.Deburring and wire drawing machine

JM is a leading manufacturer specializing in deburring and wire drawing machine. A deburring machine is a piece of equipment used in the metal processing and manufacturing industry, primarily designed to remove burrs, sharp edges, and oxide layers from workpieces, thereby improving product quality and safety. The XDP-800RPR Deburring & Brushing Machine is a highly integrated and intelligent metal surface treatment system, specifically designed for efficient deburring, chamfering, and brushing processes. Independently developed by Jianmeng, the deburring machine ensures stability and processing precision under complex working conditions through dynamic simulation and process optimization. JIANMENG offers various solutions to enhance the efficiency of metal fabrication!Electro-Hydraulic CNC Bending Machine

The Press Brake is a sophisticated and intelligent solution for sheet metal forming, engineered to meet diverse fabrication needs. Its structural frame, designed by JIANMENG Smart, utilizes PRO/E 3D modeling and finite element analysis (FEA) to ensure superior strength and stiffness compliant with global standards. Built from high-grade Q235B steel, the frame is treated with shot blasting, anti-corrosion coatings, and vibration stress-relief processes to improve mechanical stability, service life, and long-term dependability.