China Vertical CNC Grooving Machine Manufacturers, Suppliers, Factory

To consistently enhance the management method by virtue of the rule of ""sincerely, fantastic religion and top quality are the base of business development"", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for Vertical CNC Grooving Machine,V Grooving Machine With Laser Cutting,V Grooving & laser Combo Machine,Vertical v cutting machine,High-Speed Vertical V-Grooving Machine, Now we now have established steady and lengthy company associations with clients from North America, Western Europe, Africa, South America, extra than 60 countries and regions.

Vertical CNC Grooving Machine, Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Hot Products

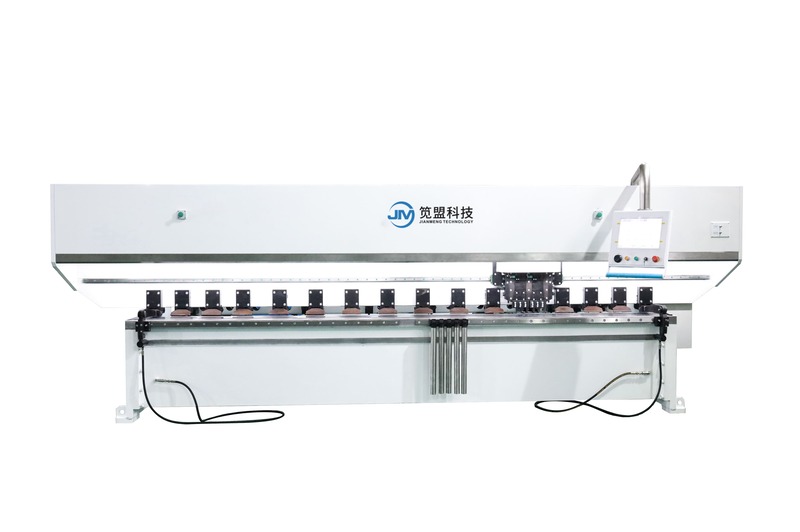

Horizontal High Speed Cutting Machine

The horizontal high speed cutting machine is a professional V cutting equipment produced by JM, a manufacturer in China with the most types of V cutting machines. The horizontal high speed cutting machines have high cost-effectiveness at medium to low utilization rates.CNC Horizontal High Speed V Grooving Machine For Stainless Steel Plates

The CNC Horizontal High Speed V Grooving Machine For Stainless Steel Plates from Chinese manufacturer JM is not only to process stainless steel plate, but also can be used for cooper plates, aluminium plates, galvanized plates and son on.CNC Press Brake

JM is a leading China CNC Press Brake manufacturers and suppliers. HARSLE is the professional factory which endeavor to manufacture eligible brake press machine for all customers in the world. Its CNC press brake is the best choice for the startup company to save money or anyone who wants to use the machine in the easy way.Pneumatic Metal Forming Machine

JIANMENG specializes in advanced Metal Shaping Machine, engineered for high-precision, chip-free processing of metal sheets with exceptionally low noise. These Metal shrinker machine support a wide range of metal forming applications, making them an ideal solution for both manufacturing new components and performing precise adjustments or repairs on existing parts. With rapid tool change capabilities and smooth transitions between functions, JIANMENG solutions are designed to maximize flexibility and efficiency. The PMF 400Metal Shaping Machine stands out with its reinforced structure and significantly increased forming pressure, enabling it to handle more demanding tasks. Its modular die system supports a variety of easily interchangeable tools—including shrinker and stretcher toolings—offering unmatched adaptability in metal forming operations. Built for long service life, high precision, and multifunctionality, JIANMENG delivers next-generation forming technology that sets a new standard for efficiency, control, and performance in modern metal fabrication.Vertical Laser & V Cutting Machine for Sheet Metal

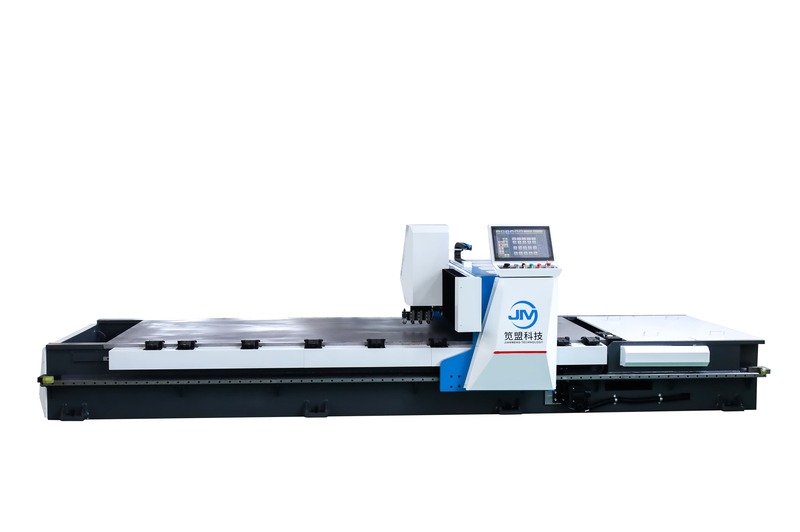

JIANMENG Laser Cutting Machine integrates high-precision laser cutting, intelligent V-grooving, and fully automated production into one system, enabling one-stop processing from flat sheet to finished workpiece. V Grooving & Laser Integrated Machine achieves positioning accuracy of up to ±0.1 mm, delivering smooth, burr-free, deformation-free edges, and is capable of machining complex irregular shapes and sharp, reflection-free bends. Vertical Laser & V Cutting Machine intelligent control system connects directly to engineering drawings, automatically completing cutting path planning, process parameter matching, and continuous whole-sheet processing. Compared with traditional multi-machine, step-by-step workflows,V Grooving & Laser Integrated Machine boosts efficiency by more than three times, reduces process changeover time by over 80%, and ensures top-tier standards in dimensional accuracy, surface quality, and design complexity—making it the ideal choice for high-end architectural decoration and artistic installations.Electric Servo CNC Press Brake

The all-electric servo press brake is a high-precision machine for sheet metal forming, featuring a robust alloy steel frame and a pure electric drive system. Utilizing servo motors, ball screws, and optical encoders, it ensures exceptional accuracy and synchronization. This oil-free design offers up to 75% energy savings, faster operation, and includes an intelligent CNC system with automatic deflection compensation for reliable, efficient, and safe high-precision bending tasks.